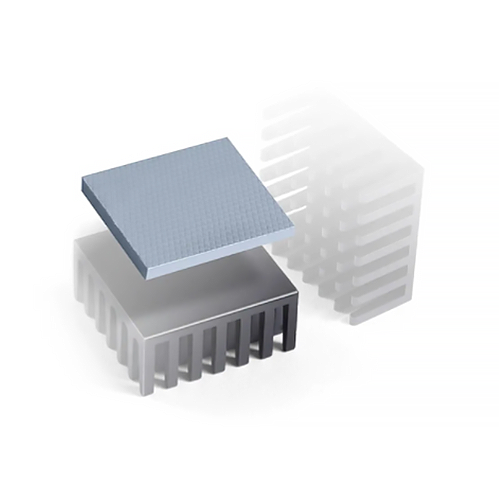

High thermal conductivity on the mount with chemical (heat resistant, insulating, chemical resistant, etc.) and physical (flexibility, elastic adhesion) properties

High thermal conductivity on the mount with chemical (heat resistant, insulating, chemical resistant, etc.) and physical (flexibility, elastic adhesion) properties

Customizing production enabled according to customer needs

Customizing production enabled according to customer needs

|

|

|

|

|

|

|

|

| ITEM | Unit | KBE-TPDS10 | KBE-TPDS30 | KBE-TPDS60 | Note |

|---|---|---|---|---|---|

| Thermal conductivity | (W/mk) | 1.0 | 3.0 | 6.0 | ASTM D5470 |

| Color | - | White, gray | White, gray | White, gray | - |

| Density | (g/cm3) | 1.6 | 3.03 | 3.4 | ASTM D792 |

| Hardness | (shore ○○) | 20~30 | 40~50 | 60~70 | ASTM D2240 |

| Volume resistance | (Ω·cm) | 1x1014 | 1x1014 | 1x1014 | ASTM D257 |

| breakdown Voltage | kV | >15 | >15 | >15 | ASTM D149 |

| Thermal stability | -40~150℃ | No change | No change | No change | - |

| Thickness | mm | 1, 2, 4 | 1, 2, 4 | 1, 2, 4 | - |

| Flame rating | UL94 | V-0 | V-0 | V-0 | - |

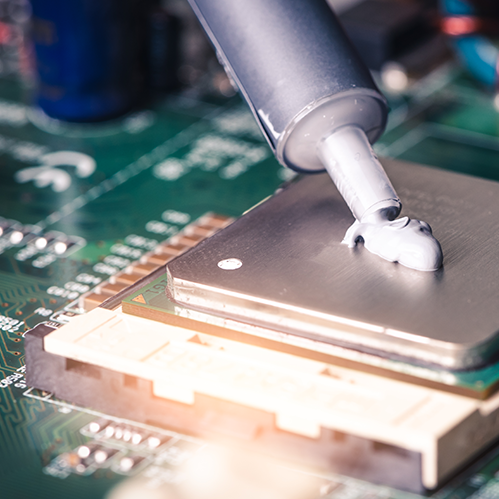

Available for both dispensing and potting with great flow; even effective in penetrating into a narrow gap; curing at room/high temperature enabled

Available for both dispensing and potting with great flow; even effective in penetrating into a narrow gap; curing at room/high temperature enabled

Customizing production enabled according to customer needs

Customizing production enabled according to customer needs

|

|

|

|

|

|

| ITEM | Unit | KT-L1000 | KT-L3000 | Note |

|---|---|---|---|---|

| Thermal conductivity | (W/mk) | 1 | 3 | ASTM D5470 |

| Viscosity(mixed) | Pa.s | 10~20 | 200~300 | Brookfield |

| Color | - | White, gray | White, gray | - |

| Density | (g/cm3) | 1.8 | 3 | ASTM D792 |

| Hardness | (shore ○○) | 20~30 | 30~40 | ASTM D2240 |

| Volume resistance | (Ω·cm) | 1x1014 | 1x1014 | ASTM D257 |

| breakdown Voltage | kV | >15 | >15 | ASTM D149 |

| Thermal stability | -40~150℃ | No change | No change | - |

| Flame rating | UL94 | V-0 | V-0 | - |

| Pot-life | 25oC/min | 60 | 60 | - |

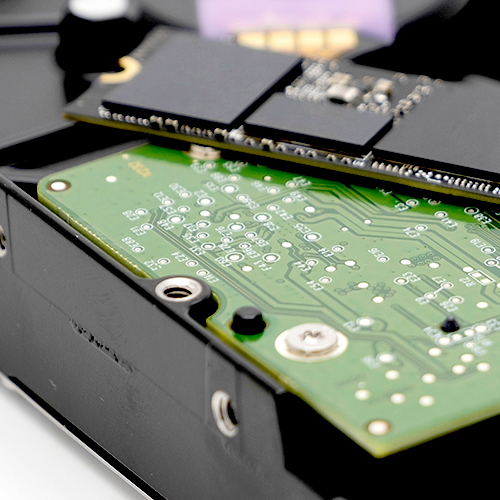

Not easy to transfer heat in electronic components which produce a lot of heat such as CPUs and AP chips and metallic covers due to a lot of hidden ups and downs

Not easy to transfer heat in electronic components which produce a lot of heat such as CPUs and AP chips and metallic covers due to a lot of hidden ups and downs

Facilitates heat transfer by removing pores between interfaces

Facilitates heat transfer by removing pores between interfaces

Customizing production enabled according to customer needs

Customizing production enabled according to customer needs

|

|

|

|

|

|

| ITEM | Unit | KT-L1000 | Note |

|---|---|---|---|

| Thermal conductivity | (W/mk) | 10 | ASTM D5470 |

| Viscosity | poise | 900 | Brookfield |

| Color | - | gray | - |

| Density | (g/cm3) | 2.5 | ASTM D792 |

| Volume resistance | (Ω·cm) | 1x1014 | ASTM D257 |

| Thermal stability | -20~120℃ | No change | - |